Social Fabric

The men and women of The Bleachery

In 1998 Springs Industries gave The Herald newspaper (Rock Hill, South Carolina) access to write a series of weekly stories on the history of the Rock Hill Printing & Finishing Company, known locally as

'The Bleachery'. About to be shut down after almost 70 years of continuous operation, The Bleachery had become too costly to modernize, without which it wouldn't be able to compete in the global market. A massive printing facility of over 2 million square feet, The Bleachery was reputed to have been the largest of its type in the world. At its peak almost 5000 people were employed there. It was the principal reason for the growth of Rock Hill. The Herald assigned 3 photographers and a writer to the project and asked me to join them.These are a few of the pictures I made.

Marlene Hinson with her 3 daughters and a picture of her father, all of whom worked at The Bleachery.

Tim Blue, Catawba Indian, water filtration plant operator, third shift.

Wylie Hemphill fixing the mercerizer. Some cloth required hardening so it could withstand rough use (kitchen table cloth, for example). To accomplish this it was run through heated caustic soda, or 'mercerized'.

Barney Nichols, yard supervisor and carpenter. An expert craftsman, Barney was also a councilor for the small town of Richburg.

Tommy Pharr, inventory stock keeper, mixing dyes.

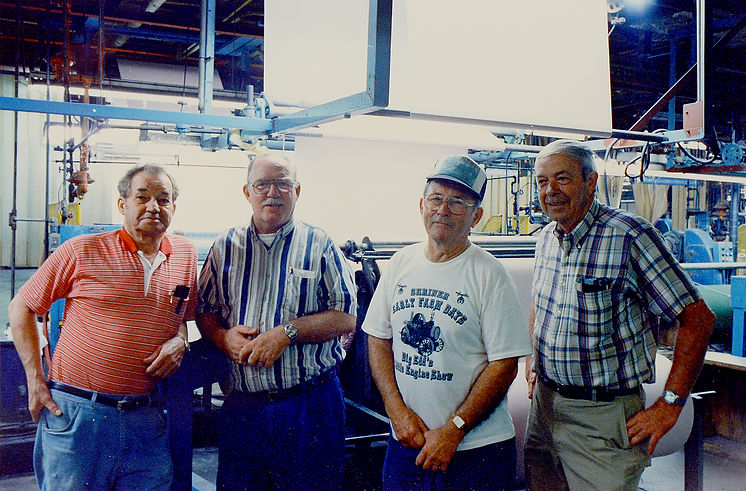

With 200 years of service among these 4 men, they represent an industrial phenomenon that we'll likely never see again - working for the same company an entire life. The Bleachery had a '50 Year Club', a feature I'd never come across before. During this project another 5 employees were inducted into the club. There were now 34 living members in the club.

Left: Roy Dunn (53 years service), Gary Rayfield (43), Tom Armour (56), right: Carl Ramsey (48).

Emile Russett, plant manager, showing us an engraved roller used in the earlier technology of 'roller printing'. The background includes rollers used on 'star wheels' where each roller printed a different part of the design in a different ink. The print machines for that technology stood 3 stories tall and required great skill to operate. By the late 1960's roller printing technology was replaced with rotary screen printing, itself replaced within 25 years by digital printers.

David Turney arranging just-printed cloth in the drying oven.

Sam Diggs, shader. Using a sample of the client's original order, the shader checks to make sure the new print matches exactly.

Luther Faile, dye printer. I was told that Luther had operated this same machine for 50 years and

knew its characteristics intimately.

Randall Hoover, engineer. The Bleachery's massive engineering shop could manufacture parts for all the plant's machines. With its equipment and the expertise of the engineers, along with the very large yard staff, The Bleachery workforce was often called upon by Rock Hill to repair city services.

Tommy Watts inspecting finished cloth before packaging.